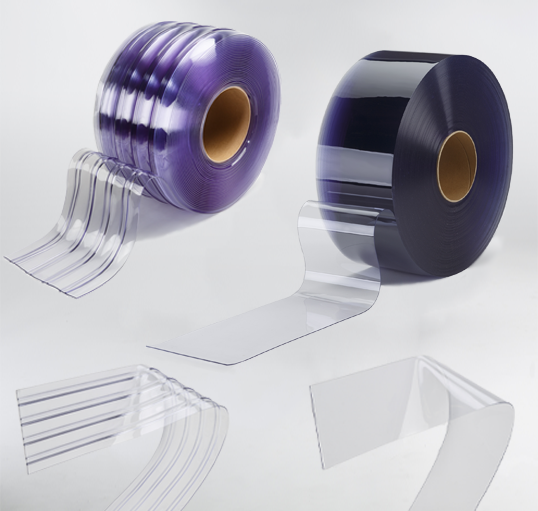

Flat Clear Standard PVC Strip Door Materials are the most commonly used strips sold on the market today, being used in approximately 90% of all applications. The flat face and smooth finish reduce drag, enabling easy passage without hindering movement. Operational temperatures between 0°F and 150°F.

Ribbed Clear Standard PVC Strip Door Material is specially designed with heavier traffic and faster movements, such as forklifts or handcarts in mind. The ribbed face has multiple benefits:

- Ribs create a thermal barrier of air pockets providing additional insulation.

- Standard offset double ribbed design reduces drag on traffic while ensuring strips do not stick together.

- Forklifts and other heavy traffic make contact with the ribs first, leaving the face of the material unscratched and clear thereby maintaining visibility and safety.

Extra low temp PVC strip door is also available and designed to withstand the most extreme conditions and temperatures ranging from -40°F and 130°F. These strips are best suited for walk in coolers, blast freezers or outside conditions.

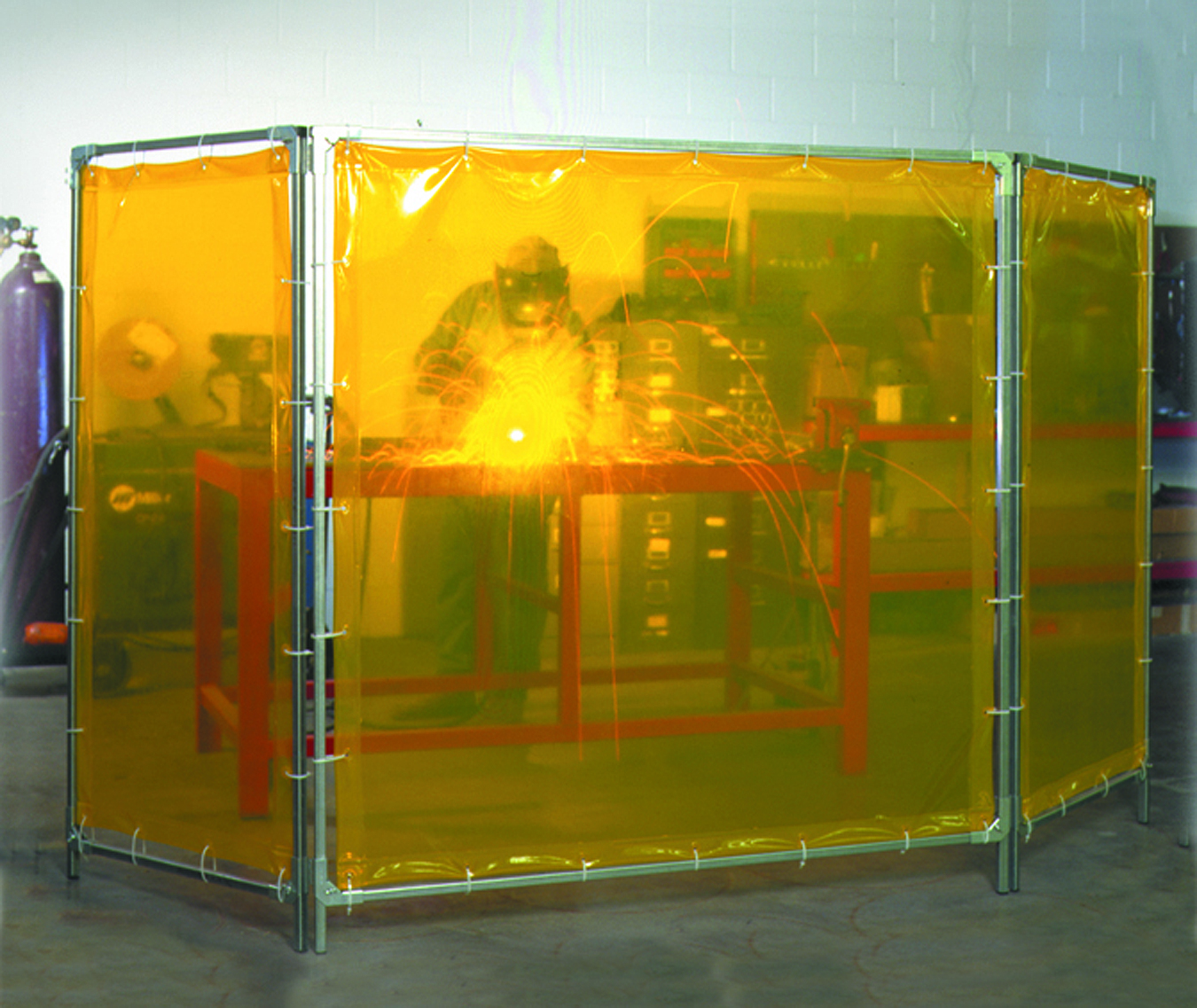

Weld screen tinted PVC strip door are used to help create dividers that are capable of blocking harmful UV light. Welding strip door material is OSHA approved and fire rated.

Anti-static strip door is used used for cleanrooms, computer rooms and data centers. All anti-static strip door meets the federal standard 101c for static discharge.